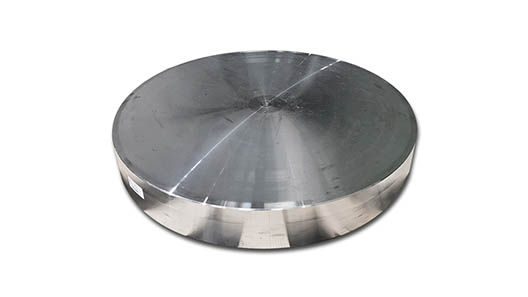

Stainless Steel 321 Forged Discs

SS 321 (Stainless Steel 321) stands out as an excellent choice, thanks to its unique properties that make it ideal for industries requiring heat and corrosion resistance. At Ferrobend, we specialize in the production of SS 321 forged discs, delivering superior products that meet the most demanding standards. With a combination of advanced manufacturing processes and an unwavering commitment to quality, we provide our clients with reliable, durable, and precisely engineered forged discs. At Ferrobend, we prioritize customer satisfaction. Our customer support team is available to assist with inquiries, offer technical advice, and ensure that our clients receive the best possible service. From initial consultation to after-sales support, we aim to build lasting relationships with our clients.

SS 321, a variant of austenitic stainless steel, is primarily composed of iron, chromium, and nickel, with titanium added to the alloy. The key characteristic of SS 321 is its high resistance to corrosion, oxidation, and its excellent performance at high temperatures. These properties make it a preferred material for various applications, especially in the aerospace, chemical, and petrochemical industries, where components are exposed to extreme conditions.

The addition of titanium to SS 321 stabilizes the material, reducing the risk of sensitization during welding. This enhances its overall strength and resistance to intergranular corrosion, making it highly suitable for welded structures and components. As a result, SS 321 is often used for manufacturing components in high-temperature environments, such as furnace parts, heat exchangers, and jet engines.

Forged discs made from SS 321 stainless steel are crucial components in many industries. These discs are used in applications that require high-strength, high-resistance, and precise engineering. Unlike cast products, forged discs are made through a process that involves the application of heat and pressure to the material. This results in a uniform structure that significantly improves the material’s strength, durability, and overall performance.

Ferrobend manufactures SS 321 forged discs with precision and expertise, ensuring each product meets the specific requirements of our customers. Forged discs are typically used in turbine components, pressure vessels, flanges, and other critical machinery. They must endure high levels of mechanical stress, temperature variations, and corrosive environments. SS 321’s properties make it a perfect choice for these demanding applications.

The forging process begins by heating the SS 321 material to the required temperature. This step is critical as the material needs to be malleable enough for shaping. Ferrobend uses advanced heating technologies that precisely control the temperature of the steel, ensuring it reaches the optimal level for forging without compromising its integrity. Once the material is heated, it is subjected to controlled pressure in a forging press. This process shapes the material into the desired disc form. The high pressure used during forging ensures that the grain structure of the material is refined, resulting in a uniform and dense structure that enhances the mechanical properties of the final product.

Quality control is a cornerstone of Ferrobend’s manufacturing process. Before shipment, every SS 321 forged disc undergoes rigorous testing to ensure it meets the necessary mechanical, chemical, and dimensional specifications. We perform non-destructive testing, hardness testing, and visual inspections to verify the integrity and performance of the product. Only when the forged discs pass these tests do we proceed to shipment.

Ferrobend has years of experience in stainless steel forging, particularly in producing SS 321 components. Our team of engineers and technicians is highly skilled in all aspects of the forging process, ensuring that each product is manufactured with precision and care.