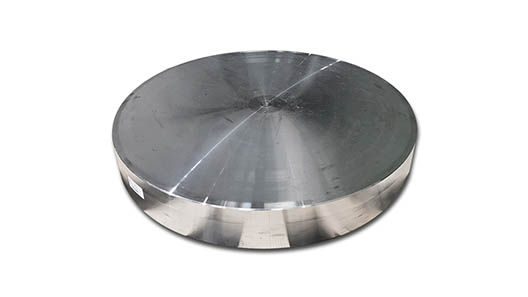

Stainless Steel 321 Forged Flanges

S 321 forged flanges have emerged as the go-to choice for industries requiring reliable and durable solutions. Ferrobend, a trusted name in flange manufacturing, is proud to offer high-quality SS 321 forged flanges, delivering unmatched strength, resilience, and performance across various industrial applications. In this article, we will explore the benefits of SS 321 forged flanges, the manufacturing process, and how Ferrobend stands out as a top-tier provider of these essential components. Ferrobend’s modern manufacturing plant is equipped with advanced machinery and equipment, ensuring that each SS 321 flange is produced with precision and consistency. The integration of the latest technology allows Ferrobend to maintain high-quality standards throughout the production process.

Stainless Steel 321 (SS 321) is a heat-resistant alloy with added titanium to prevent carbide precipitation, offering superior resistance to intergranular corrosion. This alloy's high corrosion resistance, strength, and ability to perform well in extreme conditions make it a popular choice for manufacturing flanges. SS 321 forged flanges are made from this alloy, ensuring outstanding resistance to high temperatures and oxidation. These flanges are widely used in industries like petrochemical, power generation, marine, oil and gas, and more, where high temperatures and corrosive environments are prevalent.

Forging SS 321 flanges involves shaping the metal using pressure and heat, resulting in a superior grain structure. This process enhances the mechanical properties of the flanges, making them ideal for demanding applications that require durability and reliability.

The first step in the manufacturing process is selecting premium-grade SS 321 stainless steel. Ferrobend ensures that only the highest quality materials, meeting international standards, are used in production. The raw SS 321 material is heated to a specific temperature, and then pressure is applied to shape it into the desired form. Forging improves the material's grain structure, making the flanges stronger and more durable. After forging, the SS 321 flanges are carefully machined to ensure they meet the precise dimensions required for the application. CNC machining tools are used to achieve high precision and tight tolerances.

Ferrobend’s quality control team conducts rigorous inspections and tests on every flange to ensure it meets industry standards. This includes non-destructive testing (NDT), such as ultrasonic and magnetic particle tests, to detect any internal flaws. The final step is surface finishing, which includes processes like polishing, grinding, or pickling to remove any imperfections and ensure a smooth, corrosion-resistant surface.

Ferrobend serves clients across the world, delivering SS 321 forged flanges to industries in regions such as North America, Europe, Asia, and the Middle East. Their global distribution network ensures timely delivery and support to clients worldwide. Ferrobend is committed to producing flanges that meet the highest quality standards. Each SS 321 forged flange undergoes stringent quality control measures to ensure reliability, strength, and performance in even the most demanding environments.

Ferrobend prides itself on customer satisfaction, offering excellent customer service and technical support. The company works closely with clients to ensure they receive the best possible solution for their specific needs. Ferrobend’s SS 321 forged flanges are an excellent choice for industries requiring high-strength, corrosion-resistant, and heat-resistant solutions. With their advanced manufacturing techniques, attention to quality, and expertise, Ferrobend continues to be a leader in the flange manufacturing industry. Whether you're in the petrochemical, power generation, oil and gas, or marine sectors, you can rely on Ferrobend to deliver premium SS 321 forged flanges that will meet and exceed your expectations for durability, performance, and reliability.